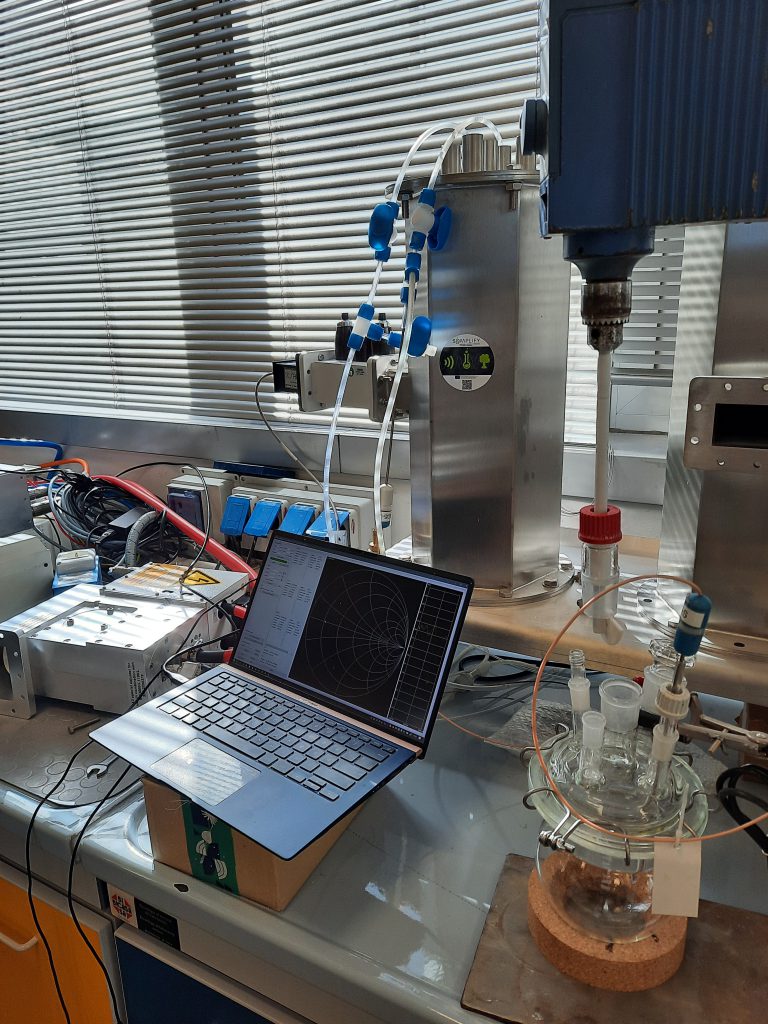

It has been designed to fulfil the requirements of continuous processing of nanoparticles. It is a twin cavity, in case one cavity is needed for the heating stage of the process and the other one for hoding the temperature.

Developed in the framework of the EU SIMPLIFY project, it allows controlling the temperature homogeneity inside the load by properly selecting load size and position. If you want to know more, please have a look at this paper (open access):

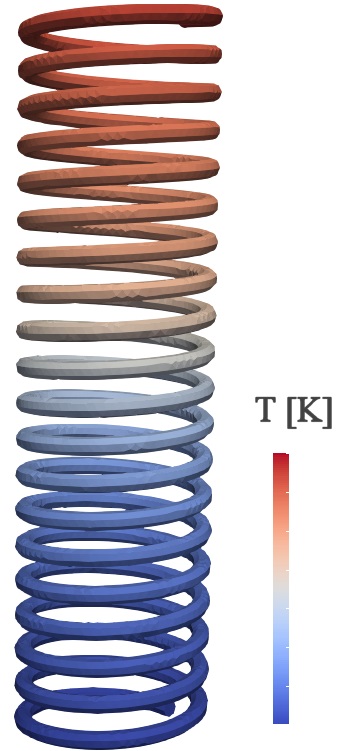

A Multi-Physic Modelling Insight into the Differences between Microwave and Conventional Heating for the Synthesis of TiO2 Nanoparticles