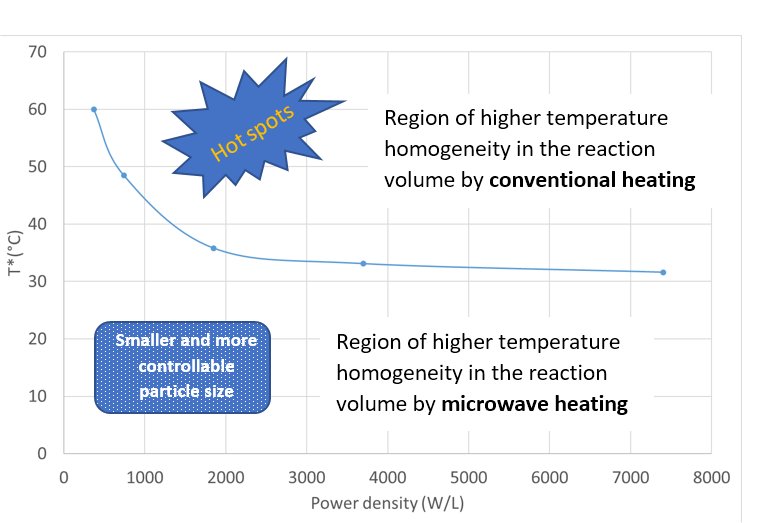

Numerical simulation is used to compare the temperature distribution existing during microwave or conventional heating by hot oil bath of a reaction volume. The simulation is applied to the sol-gel synthesis of TiO2 nanopowders, considering temperature dependent materials parameters. A WR340-based single mode applicator operating at 2.45 GHz is considered, with a cylindrical load positioned in regions of predominant electric field. A temperature homogeneity index, defined as the ratio between the average temperature and its standard deviation at a certain time, is used to compare homogeneity of conventional and microwave heating at different power densities, from 370 to 7400 W/L. Based on that comparison, a selection chart of the more homogenous heating process as a function of power density and average temperature of the reaction volume is defined and can be used to select the experimental conditions expected to lead to a more or less homogeneous particle size of the products.

A dedicated instrumented model, including three optical fibres, is developed as well, for validation purposes. Experimental validation showed a very good predictive capability of the model, with errors on estimated temperature lower than 3 °C at temperatures lower than 80 °C.

The paper describes a simple modelling-assisted method which can be useful to determine the most suitable experimental conditions to perform a microwave synthesis process, as opposed to a conventional heating one, in terms of homogeneity of temperature distribution in the reaction volume. This approach can be extended to the operation of larger microwave assisted synthesis equipment operating at the industrial scale. In this paper, this approach is applied to the sol-gel synthesis of TiO2 nanoparticles.